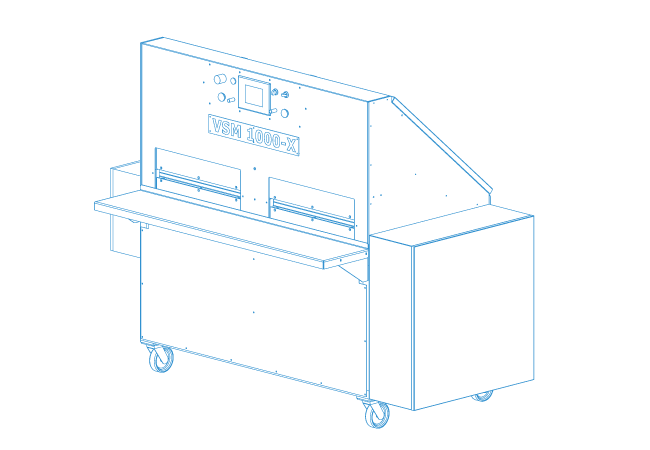

VSM® 1000-X

The semi-automatic packaging machines is characterised by its more than flexible usage options: The two vacuum stations can be activated and deactivated separately; the feet on the adjustment rollers enable easy change of position and the suction nozzles adapt automatically to the width of the bag. The optional double welding seam also increases the security of the weld.

High flexibility

and performance strength

The flexible handling, combined with the tried and tested quality and performance of the VSM® system makes the VSM®1000-X the ideal partner when packaging smaller capacities.

Advantages

- Flexible activation and deactivation of the two separate vacuum stations with automatic adaptation of the suction nozzles to the bag width

- Use-optimised and user-oriented construction

- Bi-active impulse welding with double welding seam for optimum results, even with damp bags, and a wrinkle-free welding seam

- Highest hygiene standards, easy cleaning and stainless steel manufacture

- Highest possible safety standards thanks to two-handed operation and safety-oriented design

- High performance capabilities and long-life thanks to high quality in process and spare part guarantee

-

Vacuum Packing:Automatic, 2 separate vacuum stations

-

Bagging:Manual

-

Performance:2 packages/cycle

-

Dimensions:L 2110, W 1150, H 1650 mm

-

Weld Length:max. 500 mm

-

Product Dimensions:Variable

-

Vacuum Display:Yes

-

Touch Panel:KTP 600

-

Controller:Siemens S7

-

Vacuum Pump:63m³

-

Voltage:400 V / 50 Hz

-

Control Voltage:24 VDC

-

Compressed Air:7 - 8 bar

-

VPN Connection:Available optionally

-

Double Welding Seam:Available optionally

-

Options:- Bagging aid / pneumatic bagging station

- Roller conveyor