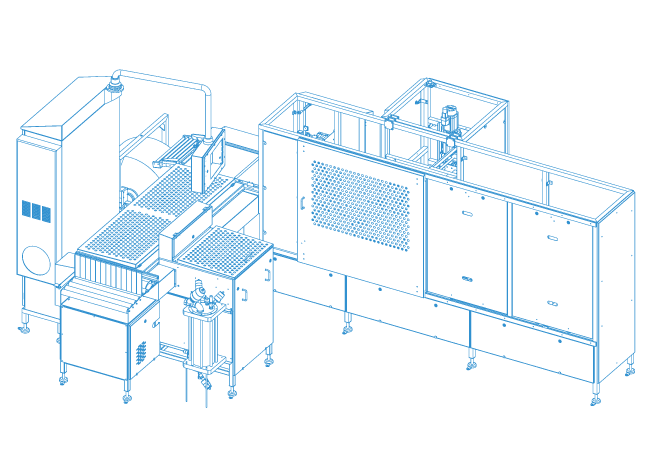

VSM® 3005-R

The fully automatic vacuum packaging machine is characterised by an automatic bagging station with roll bagger unit, as well as the subsequent fully automatic vacuum sealing and welding with the VSM® system.

This makes the VSM® 3005/4005-R the high-performing unit in your production and packaging line.

Concentrated competence

and performance strength

The VSM®3005/4005-R is the efficient and high-performing solution for fully automatic packaging.

Advantages

- Efficient and fully automatic packaging with a vacuum station in an optimised and space-saving design

- Automatic bagging of the product

- Bi-active impulse welding for optimum welding, even with damp bags, and a wrinkle-free welding seam

- Hygiene-oriented design for optimal hygiene standards

- Easy handling thanks to user-friendly, ergonomic and intuitive operation

- High performance capabilities and long-life thanks to high quality in process and spare part guarantee

- Simple integration in existing systems thanks to potential-free contacts

-

Vacuum Packing:Fully automatic, 1 vacuum station

-

Bagging:Fully Automatic

-

Performance:Up to 5 packages / minute with a standard Euroblock product size

-

Dimensions:5290 × 3440 mm

-

Weld Length:Max. 500 mm

-

Product Dimensions:Euroblock 500 x 300 x 100 mm, Tolerance +/- 5 mm

-

Vacuum Display:Yes

-

Touch Panel:KTP 900

-

Controller:Siemens S7

-

Vacuum Pump:63m³; 100m³

-

Voltage:400 V / 50 Hz

-

Control Voltage:24 VDC

-

Compressed Air:7 - 8 bar

-

VPN Connection:Available optionally

-

Double Welding Seam:Available optionally