Case Studies & Concepts

We love challenges

Not every customer has a product that can be handled with off-the-rack solutions. We try to find the right solution for every challenge with the help of creative ideas and a new perspective simply by thinking outside the box.

Here, we demonstrate a few of the special concepts and solutions in the VSM® packaging machines and special mechanical engineering sector that we have developed for our customers.

VSM® Mink2600

innovative packaging of mink

| The customer | The furs industry, Denmark |

|---|---|

| The challenge | Packaging of mink furs for space-saving transportation to Asia and thus the associated reduction in CO2 emissions per fur. |

| The solution | The development and design of a concept for innovative portioning and packaging line for the packaging of mink fur units with varying sizes. The developed solution, VSM®Mink2600, has been registered for patent. |

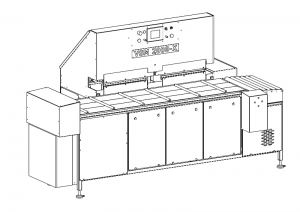

VSM® 2000-X

semi-automatic solution for different product sizes

| The customer | The cheese-making industry, Spain & Eastern Europe |

|---|---|

| The challenge | The cheese batches are not large enough for a fully automatic solution, but a partial automation is sensible and desired. The size of the products to be packaged varies considerably. |

| The solution | Development of the VSM®2000-X with manually or pneumatically supported bagging of fully automatic evacuation and welding. |

VSM®3010/4010-R

fully automatic solution for different product sizes

| The customer | The cheese-making industry, Norway |

|---|---|

| The challenge | Packaging of three different cheese sizes: 20 kg, 10 kg and 5 kg large blocks are to be packed in different batches using a single machine. |

| The solution | Adaptation of the system and the development of a quick adjustment tool that enables the machine to be quickly adapted to the appropriate cheese size for the batch, based on machine type VSM®3005. |

Semi-Automatic VSM®3000

Packaging of cheese in slim roll-format

| The customer | The cheese-making industry, Poland & Estonia |

|---|---|

| The challenge | Packaging of cheese in a very slim and long format (“salami cheese”) with extra-long and narrow bags. |

| The solution | Modification and adaptation of the vacuum packaging system for very long and at the same time, very slim product units. |

VSM® Bulky XL

VSM® Bulky goes XL: evacuation of onion barrels

| The customer | The food industry |

|---|---|

| The challenge | Evacuation of onions in brine, filled bags in barrels. Evacuation sealing from above. |

| The solution | Modification of the VSM® Bulky for the efficient evacuation and reliable welding despite the high level of moisture in the container. |

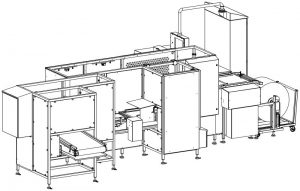

Washing System for Cheese Racks

| The customer | The cheese-making industry, Estonia |

|---|---|

| The challenge | Washing system required for cheese racks to ensure optimised hygiene standards in the dairy. |

| The solution | Development and design of a concept for compact cheese rack washing system with documentation, in accordance with specifications and currently hygiene standards. |