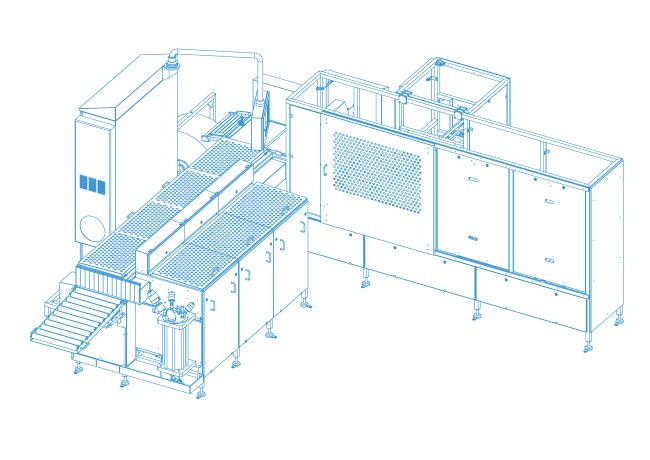

VSM® 6000-R

With the VSM®6000-R, our packaging machines have achieved a new level of productivity and efficiency. Fitted with 3 vacuum stations and numerous further developments, it is the high-performing solution for handling large capacities.

Alongside many innovations, the VSM® 6000-R relies on the tried and tested benefits of the VSM® system and with taped bags on roll also ensures reliable and quick packaging results.

The new generation of VSM® systems

The VSM®6000-R is the power package for automatic packaging and vacuum sealing on a large scale.

Advantages

- Extremely efficient and high-performance packaging with 3 vacuum stations

- Innovative & optimised bagging of the product

- Bi-active impulse welding for optimum welding, even with damp bags, and a wrinkle-free welding seam

- Hygiene-oriented design for optimal hygiene standards

- Easy handling thanks to user-friendly, ergonomic and intuitive operation

- High performance capabilities and long-life thanks to high quality in process and spare part guarantee

- Simple integration in existing systems thanks to potential-free contacts

-

Vacuum Packing:Fully automatic, 3 vacuum stations

-

Bagging:Fully Automatic

-

Performance:Up to 14 packages / minute with a standard Euroblock product size

-

Dimensions:5170 × 5905 mm

-

Weld Length:max. 500 mm

-

Product Dimensions:Euroblock 500 x 300 x 100 mm, Tolerance +/- 5 mm

-

Vacuum Display:Yes

-

Touch Panel:KTP 900

-

Controller:Siemens S7

-

Vacuum Pump:63m³; 250m³

-

Voltage:400 V / 50 Hz

-

Control Voltage:24 VDC

-

Compressed Air:7 - 8 bar

-

VPN Connection:Available optionally

-

Double Welding Seam:Available optionally