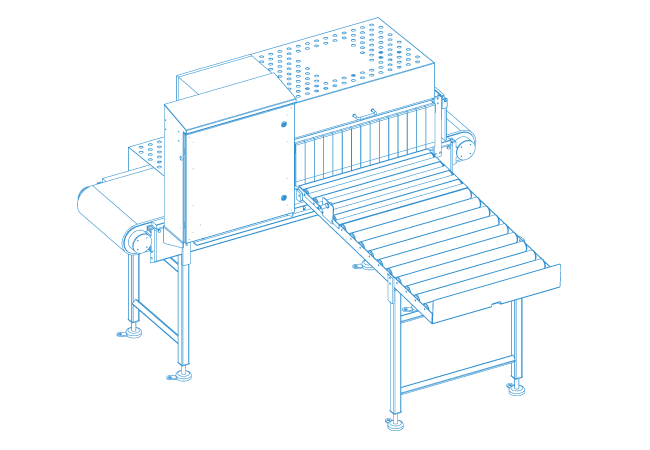

VSM® LT100 / 200

Inspired by the manual vacuum testing method that cheese-makers use, the vacuum testers VSM®LT100 and LT200, are the perfect addition to fully automatic vacuum packaging machines with the VSM® system.

Optimally designed for use with the VSM® packaging machines, the vacuum tester inspects the packages for leaks. A special rubber is used to test the packaging and sorted them out in the event of a leak.

Safety when vacuuming,

for a smooth process

The integration of a vacuum tester should not create a bottleneck within the production line; instead it should be simple and easy to incorporate it into the procedure. The VSM®LT100 has one test station and is coordinated perfectly for the output of the VSM®3005/4005-R. The VSM®LT200 has two test stations and is ideal for use with the increased output of a VSM®5005/4005-R. Potential-free contacts enable the vacuum tester to be integrated flexibly into the packaging line downstream of the packaging machine.

LT100

- 1 test station with special rubber testers

- Roller conveyor for sorted out packages; volumes for up to 3 packages per test station

- User-friendly operation, e.g. quick and easy change of special rubber tester without the need for tools

- Parameters can be adapted via the touch panel

- Potential-free contacts

LT200

- 2 test stations with special rubber testers

- Roller conveyor for sorted out packages; volumes for up to 6 packages per test station

- User-friendly operation, e.g. quick and easy change of special rubber tester without the need for tools

- Parameters can be adapted via the touch panel

- Potential-free contacts